With so many types of hoses that are available in the market, choosing a right hose that suits your application can be a mind boggling and/or fogging issue. PVC? Rubber? Fabric? Composite? Metal? Pipes? Wire? Non-wired? Suction or Delivery? WHAT!?

There is not a definite RIGHT type of hose to use or purchase, it all boils down to what application are you going to use it with.

Stainless steel hoses remain a very popular choice for fluid transfer or control applications. They are used in a wide range of industries such as food processing, biomedical, oil and gas, chemical plants etc. They are available in several different grades/alloys to better suit different applications.

So, when do you really need metal hoses? Consider these criteria below when choosing a metal hose:

Stainless Steel hose has good versatility, durability and outstanding price-to-quality ratio. As a metal, it is tough, malleable, formable, strong and modifiable; it is also a good fit for extreme pressure and temperature applications and to protect plant and worker from harm and potential catastrophic failure.

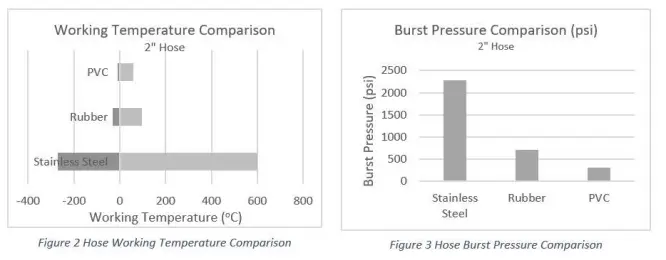

Above charts compare the properties of one of our Stainless-Steel hose (Kingflex® Series P3 with single braid) to the average property value of various rubber and PVC hoses. Clearly, both charts show that Stainless Steel hose has a much better mechanical properties than rubber or a PVC hose type.

Mechanical properties of Stainless-Steel hoses can be enhanced by layers of braids, pitch and wall thickness.

Stainless steel is a chemical resistance metal that can convey corrosive chemicals. This special property serves as one of the main driving factors for its high demand.

Different from normal steel/carbon steel, Stainless Steel has a 1-3nm (Hedberg & Wallinder, 2016) thin passive oxide layer that protects the underlying iron (Fe) from being oxidised. The special layer creates the chemical resistance property of the stainless steel we know (Brytan, 2016).

If we compare Stainless Steel’s chemical resistance to Carbon Steel, the metal has more A and B and less C and D rating than Carbon Steel (CS). This shows that Stainless Steel has better chemical resistance than Carbon Steel (Habonim, 2013).

Gas permeation is the penetration of a gas through a solid. Stainless Steel and metal hose are not susceptible to gas permeation. This property is important if the gas media needs to be contained or if high purity product is desired. The rate of permeation depends on the size of the gas molecule; smaller gas molecule will have a faster permeation rate.

Stainless Steel Hose can maintain its shape and form in the event of suction/vacuum. Non-metal hoses typically will collapse in negative pressure and in the absence of support. Hose collapse will damage the hose and risk the safety of the workers and surrounding amenities.

Stainless Steel Hose can incorporate any type and configuration of weldable fitting into their assembly while other hose types might require some special shanks or ferrule. This benefit can simplify the assembly, increase its pressure rating and reduce potential leakage points.

Since Stainless Steel is a strong conductor, it does not build-up static charge. This provide greater safety for the metal hose as static charge can be easily grounded (Production Automation Corporation, n.d.). Non-conductive hose like rubber hose hinders the electron flow, allowing it to accumulate and be discharged. Static discharge might be lethal depending on the situation.

With so many advantageous traits to it, stainless steel hose does sound like it is ALMOST a everything hose. But oh wait, WHEN AND WHERE NOT TO USE stainless steel hoses?

Stainless steel is still a metal alloy, which can corrode especially in chloride and reducing environment (Hedberg & Wallinder, 2016).The introduction of reducing agent will attack the passive layer which will lead to local corrosion such as pitting or crevice corrosion.