Stainless steel hose braid serves as the “flexing muscle” to resist internal and external pressure and to provide protection against abrasion and contamination When compared to non-braided hose, braided hose can prevent longitudinal expansion and protect the hose’s shape and flexibility (Wikipedia, 2018). It is also highly flexible and can mould itself to follow the movement of the hose (S. Hasan, 2018).

Stainless steel hose braids come in a variety of choices that caters to specific needs or applications. Materials available upon request includes:

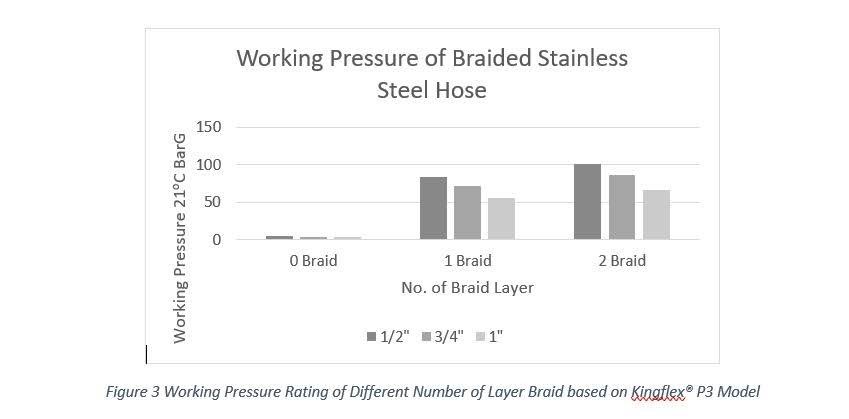

Multiple layers of braid are frequently used to enhance the strength and coverage of hose assembly (The Association for Hose and Accessories Distribution, 2015); Hence, hose with more braid layer is used for high-pressure application. Below chart shows the working pressure of different number of braid layers:

However, the weight of the assembly shall increase with the number of braid layers. Check out the application’s pressure requirement to make sure you use the right number of braids.

Wah Joo Seng provides customised quality braided metal hose assemblies in an assortment of materials, sizes, braid layers and various types of end connections to suit different applications. Our assemblies are painstakingly done locally in-house. Drop us an email at enquiry@kingflex.com or call+65 62983211 to find out more. We love to hear from you!

Looking for more? Browse through our products here or check out more of our stainless-steel hose articles