In our previous blog, we talked about the most common flange types used in the industry. Today, we would like to discuss on another important aspect of a flange – flange face. Understanding flange faces plays a crucial role to ensure that the right fit, right gasket and safety can be applied.

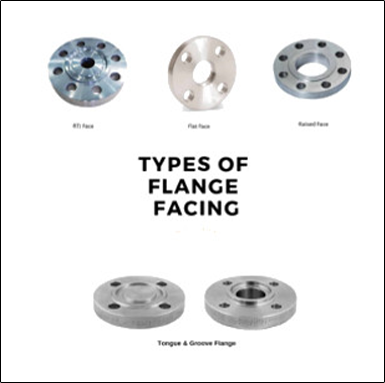

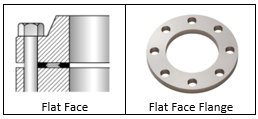

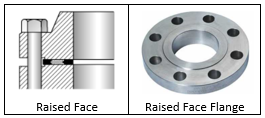

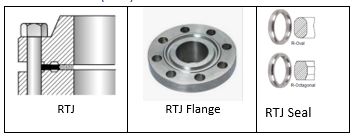

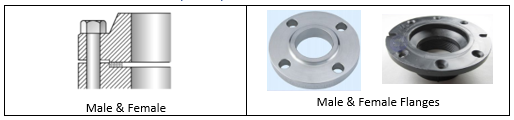

Flange face is the surface where contact between two flanges occur. A sealing component is generally introduced between the mating surface, such as metal or gasket. Below is a compilation of flange facing types that are commonly recognized in the market.

If you are looking for any flanges, you may want to contact us at (65) 6298 3211 or enquiry@wahjooseng.com. Wah Joo Seng can assemble, deliver and supply our hose assemblies with flanges! Check out our flange collections here!

https://hardhatengineer.com/

http://www.wermac.org/flanges/flanges_welding-neck_socket-weld_lap-joint_screwed_blind.html

https://www.eng-tips.com/viewthread.cfm?qid=191786